Cryogenic Bobtail Tanks

Transport tanks for air gases are designed and manufactured for your liquid distribution operations at a minimal cost for years to come with the requirements for safe and easy.

The Highlights of ISISAN transport tanks:

CrT series tanker bobtail and semitrailer are designed for the road transport with super insulations for long-term storage of extreme cold liquids with high quality vacuum level and low evaporation rate.

Low operation costs by the high payload to tare weight with optimization of the every area of the design and the materials utilized.

Safety and comfortable operation because of, improved ergonomics design and easily accessible valves in servicing.

Low operation cost by using the powerful pumps decreased unloading time and powerful pressure raising unit ensures faster pressurization.

Take care of the low centre of the gravity improved road handling and excellent stability for more safety transportation.

Long term durability and reliability because of all steel design, stainless control piping's, valves and welded connections, equipment supplied by the leaders in each area.

High performance safety system with dual relief valves and rupture discs by the diverter valves as standard.

All tankers and their components are cleaned for oxygen services.

Next to our range of standard transport tanks, ISISAN can provide you with a wide range of tailor made transport solutions likely regulatory requirments.

ISISAN tankers are des igned and manufactured in accordance with the latest international regulations such as ADR and the TPED have been incorporated or other national regulations, as required.

ISISAN cryogenic tanker manufacturer facility is ISO 9000 approved to assure the best quality in all aspects of our operation.

| Design Code | EN 13530 - ADR | |||

| Max. Allowable Working Pressure | 3 bar / 16 bar | |||

| Design Temperature | -196°C | |||

| Inner Vessel Material | Stainless Steel (According to EN 10028-7) | |||

| Outer Vessel Material | Carbon Steel (According to En 10025/EN10028-3) | |||

| Insulation | Super Insulation & Vacuum | |||

| High Pressure Series Air Gas Transport Tank | |||||||||

| LOX | LOX | LOX | LOX | ||||||

| Tank Volume | It | 6500 | 9000 | 11500 | 14000 | ||||

| Net Water Capacity | It | 6350 | 8900 | 11450 | 14040 | ||||

| Tank Empty Weight | kg | 4200 | 5020 | 6065 | 7490 | ||||

| Liquid (0.5 barg) | kg | 6800 | 9450 | 12160 | 14920 | ||||

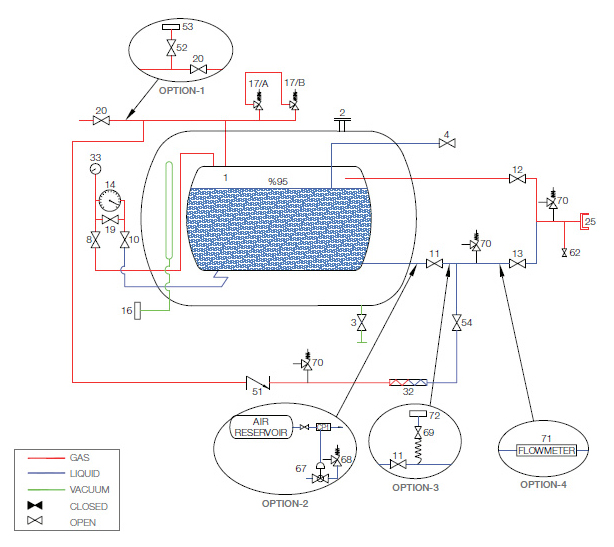

Air Gas Transport Tanks P&ID High Pressure Series

| NOMENCLATURE | |||||

| 1 | Jacketed Pressure Vessel | 17/A | Inner Vessel Safety Relief Valve | Option 1 | |

| 2 | Vacuum Safety Device | 17/B | Inner Vessel Safety Relief Valve | 52 | Gas Analysis Valve |

| 3 | Evacuation Valve | 19 | Equalizer Valve | 53 | Gas Analysis Connection |

| 4 | Try Cock Valve | 20 | Vapor Vent Valve | Option 2 | |

| 8 | Low Pressure Shut-Off Valve | 25 | Fill Connection | 67 | Emergency Shut-Off Valve |

| 10 | High Pressure Shut-Off Valve | 32 | Pressure Building Coil | 68 | Thermal Relief Valve |

| 11 | Bottom Fill Isolating Valve | 33 | Pressure Indicator | Option 3 | |

| 12 | Top Fill Valve | 51 | Non-Return Valve | 69 | Liquid Analysis Valve |

| 13 | Bottom Fill Valve | 54 | Pressure Build-up Valve | 72 | Liquid Analysis Connection |

| 14 | Level Indicator | 62 | Purge Valve | Option 4 | |

| 16 | Evacuation Connection | 70 | Thermal Relief Valve | 71 | Flowmeter |