LCO2 Bobtail Tanks

CoT Series tanks are designed, fabricated, tested and inspected to comply with national and international requirements. ISISAN tanks available with EN 14398 / EN 14025, ADR, TPED 99/36/EC and further European approvals, are used worldwide.

| TRANSPORT TANKS | ||

| Design Code | EN 14398 / EN 14025 + ADR | |

| Inner Vessel Material | Duplex Stainless Steel | Carbon Steel (EN 10028-3) |

| Max. Allowable Working Pressure | 23 Bar | 24 Bar |

| Design Temperature | -40 / +50 °C | |

| Insulation | Foam Insulation with Aluminium Jacket | |

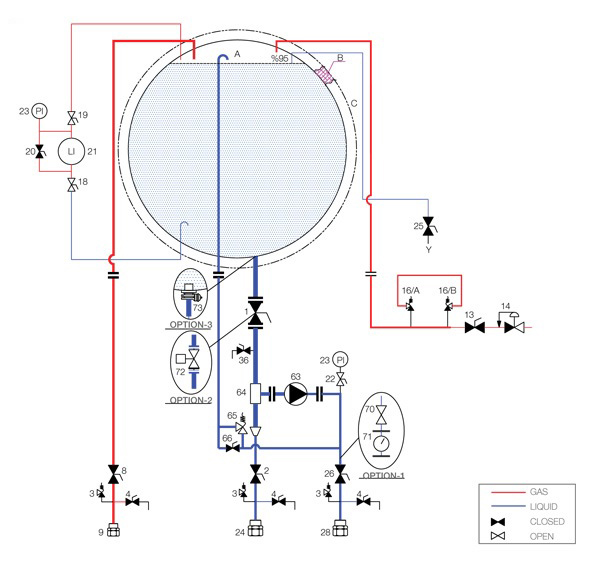

CO2 Transport Tanks P&ID

| NOMENCLATURE | |||||

| 1 | Liquid Fill Valve | 22 | Manometer Valve | OPTION-1 Flow Meter System | |

| 2 | Bottom Fill Valve | 23 | Manometer | 70 | Flow Meter Isolating Valve |

| 3 | Thermal Relief Valve | 24 | Fill Connection | 71 | Flow Meter |

| 4 | Purge Valve | 25 | Try Cock Valve | ||

| 8 | Vapor Equalizing Valve | 26 | Liquid Withdrawal Valve | OPTION-2 Main Liquid Valve with Actuator | |

| 9 | Vapor Equalizing Connection | 28 | Liquid Withdrawal Connection | 72 | Main Liquid Valve with Actuator instead of 1 |

| 13 | Regulator Isolating Valve | 35 | Analysis Liquid Valve | ||

| 14 | Back Pressure Regulator | 63 | Pump | OPTION-3 Internal Valve | |

| 16/A | Inner Vessel Safety Relief Valve | 64 | Filter | 73 | Internal Valve |

| 16/B | Inner Vessel Safety Relief Valve | 65 | Automatic By-pass Valve | A | Inner Vessel |

| 18 | High Pressure Shut Off Valve | 66 | Manual By-pass Valve | B | Foam Insulation |

| 19 | Low Pressure Shut Off Valve | C | Outlet Jacket | ||

| 20 | Equalizing Valve | ||||

| 21 | Level Indicator | ||||