LCO2 Storage Tanks / Foam Insulated

CoVCF / CoHCF series tanks are vertical or horizontal storage tanks are designed and manufactured for CO2 and N2O services with inner vessel in carbon steel. CoVCF / CoHCF pressure containing vessel is insulated with a conventional insulating material such as expanded polyurethane. The sealed cladding made of stainless steel or aluminium, protects the insulation against mechanical damage and prevents any moisture penetrating into the insulation. The conventionally insulated vessels are fitted with refrigeration units, condensing the boil off gas resulted from heat input.

The Highlights of ISISAN tanks are:

CoVCF / CoHCF series tanks are vertical or horizontal, stationary pressure vessels with polyurethane insulation; for long-term storage of cold liquids, utilizing a high performance heat insulation enabling low evaporation rates.

In addition to our standard range of tanks, ISISAN can provide you a wide range of tailor made storage solutions up to 300,000 lt with a Maximum Allowable Working Pressure of 22 or other pressures as required.

ISISAN bulk tanks are designed and manufactured in accordance with and conforming to EC directive PED 97/23/CE and AD2000, EN 13445 or other national pressure vessel codes as required.

ISISAN’s cryogenic tank manufacturing facility is ISO 9000 approved to assure the best quality in all aspects of our operation.

The support legs used are calculated according to UBC, Eurocode standards to resist high wind and earthquake loads.

Carefully designed stainless steel pipe work to reduce filling operation time. Appropriate bending of stainless steel pipe work means fewer connections, minimizing potential leaks, higher operability and less servicing.

High quality stainless steel pressure gauge, a differential pressure contents gauge or load cell are standard; with optional switches, transmitter and/or telemetry unit.

High performance safety system with dual relief valves by the diverter valves as standard.

Easily accessible valves and safety relief valve outlets directed away from the operating area, enables safe operation.

Moisture protection.

| DESIGN CODE | AD 2000 CODE-PED 97/23/EC |

| DESIGN PRESSURE | 22 Bar |

| DESIGN TEMPERATURE | -40 / +50 °C |

| MATERIAL | Carbon Steel |

| INSULATION | Foam Insulation |

*Design and manufacturing can be done according to ASME, or other design codes upon customer's requirements.

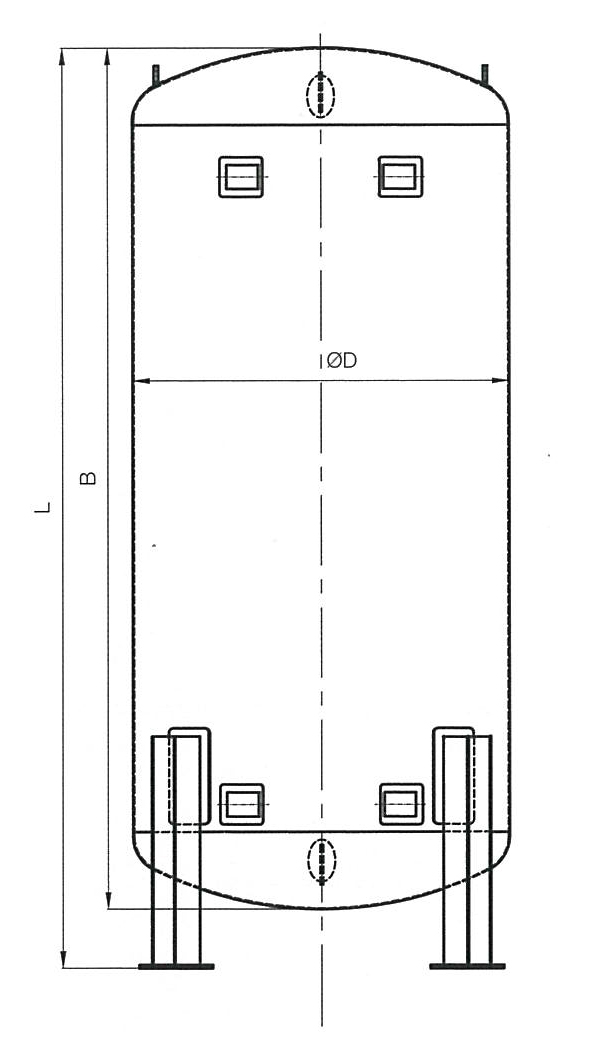

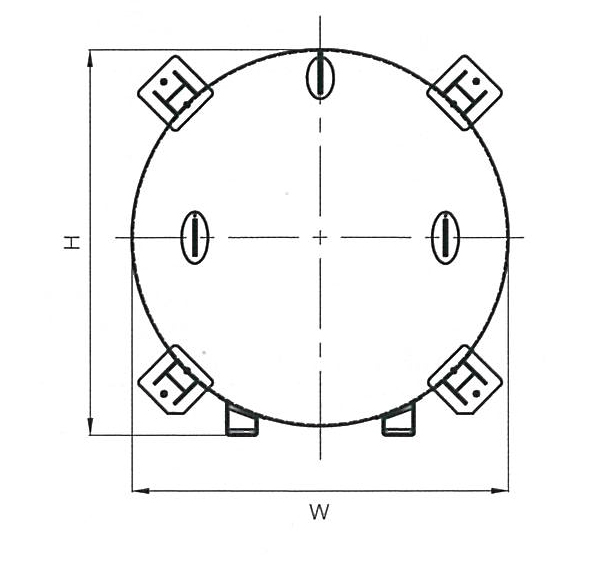

| 22 Bar Foam Insulated CO2 Storage Tanks | |||||||||

| MAWP | Gross Capacity | Net Capacity (%95 Filling) |

0D | 0D1 | L | L1 | W | H | Empty Weight |

| bar | liters | liters | mm | mm | mm | mm | mm | mm | kg |

| 22 | 6600 | 6270 | 1550 | 1950 | 3870 | 4610 | 1950 | 2190 | 2400 |

| 10000 | 9500 | 1850 | 2250 | 4060 | 4750 | 2300 | 2540 | 3500 | |

| 13620 | 12939 | 1850 | 2250 | 5560 | 6240 | 2300 | 2540 | 4400 | |

| 17600 | 15200 | 1850 | 2250 | 7090 | 7740 | 2300 | 2540 | 5300 | |

| 21500 | 20425 | 1850 | 2250 | 8560 | 9240 | 2300 | 2540 | 6200 | |

| 25460 | 24187 | 1850 | 2250 | 10060 | 10740 | 2300 | 2540 | 7200 | |

| 34000 | 31160 | 2300 | 2700 | 8820 | 9470 | 2700 | 2970 | 9400 | |

| 40000 | 36765 | 2300 | 2700 | 10320 | 10970 | 2700 | 2970 | 10800 | |

| 41000 | 38950 | 2750 | 3150 | 7540 | 8180 | 3150 | 3440 | 10700 | |

| 46000 | 42370 | 2300 | 2700 | 11820 | 12470 | 2700 | 2970 | 12200 | |

| 50000 | 47500 | 2300 | 3150 | 12920 | 13570 | 2700 | 2970 | 13200 | |

| 50000 | 47500 | 2750 | 3150 | 9040 | 9680 | 3150 | 3440 | 12500 | |

| 58000 | 55100 | 2750 | 3150 | 10540 | 11180 | 3150 | 3400 | 14200 | |

| 80000 | 76000 | 3200 | 3600 | 10780 | 11740 | 3600 | 3890 | 20000 | |

| 103000 | 97850 | 3200 | 3600 | 13780 | 14740 | 3600 | 3890 | 24600 | |

| 150000 | 142500 | 3200 | 3600 | 19780 | 20740 | 3600 | 3890 | 33500 | |

| 199000 | 189050 | 4000 | 4400 | 17500 | 18430 | 4400 | 4690 | 40200 | |

| 254000 | 241300 | 4000 | 4400 | 22000 | 22930 | 4400 | 4690 | 51000 | |

| 300000 | 285000 | 4000 | 4400 | 25750 | 26680 | 4400 | 4540 | 61500 | |